Conventionally, wireless-controlled robots use RF

circuits, which have the drawbacks of limited working range, limited

frequency range and limited control. Use of a mobile phone for

robotic control can overcome these limitations. It provides the

advantages of robust control, working range as large as the coverage

area of the service provider,no interference with other controllers and up

to twelve controls.

Although the appearance and capabilities of robots vary

vastly, all robots share the features of a mechanical, movable

structure under some form of control. The control of robot involves

three distinct phases: perception, processing and action. Generally,

the preceptors are sensors mounted on the robot, processing is done

by the on-board microcontroller or processor, and the task

(action) is performed using motors or with some other actuators.

Project overview:

In this project, the robot is controlled by a mobile

phone that makes a call to the mobile phone attached to the

robot. In the course of a call, if any button is pressed, a tone

corresponding to the button pressed is heard at the other end of the

call. This tone is called ‘dual-tone multiple-frequency’ (DTMF)

tone. The robot perceives this DTMF tone with the help of the phone

stacked in the robot.

The received tone is processed by the ATmega16

microcontroller with the help of DTMF decoder MT8870. The decoder

decodes the DTMF tone into its equivalent binary digit and this

binary number is sent to the microcontroller. The

microcontroller is preprogrammed to take a decision for

any given input and outputs its decision to motor drivers in

order to drive the motors for forward or backward motion or a

turn.

The mobile that makes a call to the mobile phone stacked

in the robot acts as a remote. So this simple robotic

project does not require the construction of receiver

and transmitter units.

DTMF signaling is used for telephone signaling over the

line in the voice- frequency band to the call switching

center. The version of DTMF used for telephone tone dialing is

known as ‘Touch-Tone.’

DTMF assigns a specific frequency (consisting of two

separate tones) to each key so that it can easily be identified

by the electronic circuit. The signal generated by the

DTMF encoder is a direct algebraic summation, in real time,

of the amplitudes of two sine (cosine) waves of different

frequencies, i.e., pressing ‘5’ will send a tone made by adding 1336

Hz and 770 Hz to the other end of the line. The tones and assignments

in a DTMF system are shown in Table I.

Circuit description:

Fig. 1 shows the block diagram of the microcontroller-based

mobile phone operated land rover. The important components of this

rover are a DTMF decoder, microcontroller and motor driver.

An MT8870 series DTMF decoder is used here. All types of the

MT8870 series use digital counting techniques to detect and decode

all the 16 DTMF tone pairs into a 4-bit code output. The built-in

dial tone rejection circuit eliminates the need for pre-filtering.

When the input signal given at pin 2 (IN-) in single-ended input

configuration is recognized to be effective, the correct 4-bit decode

signal of the DTMF tone is transferred to Q1 (pin 11) through Q4 (pin

14) outputs.

Table II shows the DTMF data output table of MT8870. Q1

through Q4 outputs of the DTMF decoder (IC1) are connected to port

pins PA0 through PA3 of ATmega16 microcontroller (IC2) after

inversion by N1 through N4, respectively.

The ATmega16 is a low-power, 8-bit, CMOS microcontroller

based on the AVR enhanced RISC architecture. It provides the

following features: 16 kB of in-system programmable Flash

program memory with read-while-write capabilities, 512 bytes of

EEPROM, 1kB SRAM, 32 general-purpose input/output (I/O) lines and 32

general-purpose working registers. All the 32 registers are directly

connected to the arithmetic logic unit, allowing two

independent registers to be accessed in one single instruction

executed in one clock cycle. The resulting architecture is

more code-efficient.

Outputs from port pins PD0 through PD3 and PD7 of the

microcontroller are fed to inputs IN1 through IN4 and enable pins

(EN1 and EN2) of motor driver L293D, respectively, to drive two

geared DC motors. Switch S1 is used for manual reset. The

microcontroller output is not sufficient to drive the DC motors, so

current drivers are required for motor rotation.

The L293D is a quad, high-current, half-H driver designed to

provide bidirectional drive currents of up to 600 mA at voltages from

4.5V to 36V. It makes it easier to drive the DC motors. The L293D

consists of four drivers. Pins IN1 through IN4 and OUT1 through OUT4

are input and output pins, respectively, of driver 1 through

driver 4. Drivers 1 and 2, and drivers 3 and 4 are enabled by

enable pin 1 (EN1) and pin 9 (EN2), respectively. When enable input

EN1 (pin 1) is high, drivers 1 and 2 are enabled and the outputs

corresponding to their inputs are active. Similarly, enable input EN2

(pin 9) enables drivers 3 and 4.

Software description:

The software is written in ‘C’ language and compiled using

CodeVision AVR ‘C’ compiler. The source program is converted into hex

code by the compiler. Burn this hex code into ATmega16 AVR

microcontroller.

The source program is well commented and easy to understand.

First include the register name defined specifically for ATmega16 and

also declare the variable. Set port A as the input and port D as the

output. The program will run forever by using ‘while’ loop. Under

‘while’ loop, read port A and test the received input using ‘switch’ statement.

The corresponding data will output at port D after testing of

the received data.

Working:

In order to control the robot, you need to make a call to the

cell phone attached to the robot (through head phone) from any phone,

which sends DTMF tunes on pressing the numeric buttons. The cell

phone in the robot is kept in ‘auto answer’ mode. (If the mobile does

not have the auto answering facility, receive the call by ‘OK’ key on

the rover-connected mobile and then made it in hands-free mode.) So

after a ring, the cellphone accepts the call.

Now you may press any button on your mobile to perform

actions as listed in Table III. The DTMF tones thus produced are

received by the cellphone in the robot. These tones are fed to the

circuit by the headset of the cellphone. The MT8870 decodes

the received tone and sends the equivalent binary number to the

microcontroller. According to the program in the microcontroller, the

robot starts moving.

When you press key ‘2’ (binary equivalent 00000010) on

your mobile phone, the microcontroller outputs ‘10001001’ binary

equivalent. Port pins PD0, PD3 and PD7 are high. The high output at

PD7 of the microcontroller drives the motor driver (L293D). Port pins

PD0 and PD3 drive motors M1 and M2 in forward direction (as per Table

III). Similarly, motors M1 and M2 move for left turn, right turn,

backward motion and stop condition as per Table III.

Construction:

When constructing any robot, one major mechanical constraint

is the number of motors being used. You can have either a two-wheel

drive or a four-wheel drive. Though four-wheel drive is more complex

than two-wheel drive, it provides more torque and good

control. Two-wheel drive, on the other hand, is very easy to construct.

Top view of a four-wheel-driven land rover is shown in Fig.

3. The chassis used in this model is a 10×18cm2 sheet made up of

parax. Motors are fixed to the bottom of this sheet and the circuit

is affixed firmly on top of the sheet. A cellphone is also mounted on

the sheet as shown in the picture.

In the four-wheel drive system, the two motors on a side are

controlled in parallel. So a single L293D driver IC can drive the

rover. For this robot, beads affixed with glue act as support wheels.

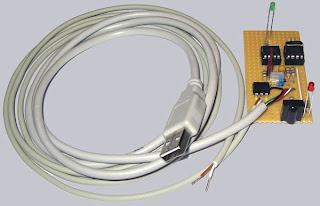

Tip and Ring:

Most of the readers cant pass this term 'Tip' and 'Ring'; so for

your convenience lets try to solve this. First of all identify the tip and ring

with the help of the figure, given below, then use the DMM and apply the short

circuit test to know the unknown wires.

For short circuit test select the 'buzzer' sign in the DMM then

connect the one lead tip and the other with the hand frees cut wires one by

one, when you hear the beep you got it! that is you wire, the tip wire.

Similarly, now connect the DMM lead to ring the other with the rest of the

wires and do the same. Cut the hand frees wire before the mike. I hope it ll

work for you guys.

Component Required:

IC1 -

MT8870 DTMF decoder

IC2 -

ATmega16 AVR microcontroller

IC3 -

L293D motor driver

IC4 -

74LS04 NOT gate

D1 -

1N4007 rectifier diode

R1, R2 -

100-kilo-ohm

R3 -

330-kilo-ohm

R4-R8 -

10-kilo-ohm

C1 -

0.47μF ceramic disk

C2, C3, C5, C6 - 22pF ceramic disk

C4 -

0.1μF ceramic disk

XTAL1 -

3.57MHz crystal

XTAL2 - 12MHz

crystal

S1 -

Push-to-on switch

M1, M2 - 6V,

50-rpm geared DC motor

Batt. -

6V, 4.5Ah battery