USB Ultra Infrared Receiver to remote

control and power on/off the PC

Today, another

interesting infrared receiver solder guide for the PC is finished.

Who like to control the PC or HTPC comfortable from the sofa, can solder different IR receiver types for commercially available universal remote controls.

There are some self building guides in the ocinside.de modding section for several years

and today a new special infrared receiver soldering guide for the PC is published.

Who like to control the PC or HTPC comfortable from the sofa, can solder different IR receiver types for commercially available universal remote controls.

There are some self building guides in the ocinside.de modding section for several years

and today a new special infrared receiver soldering guide for the PC is published.

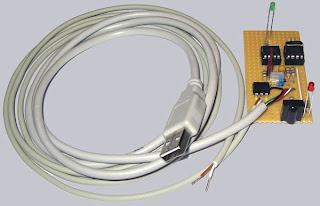

After the

extended guide for the infrared receiver with hardware side function

to remotely switch the PC ON or OFF as full USB variant with

the name "USB Ultra infrared receiver" or briefly "USB Ultra

IR" a new version 2.0 is now available.

The new USB

Ultra infrared receiver v2.0 was - contrary to the previous version - extended

by some electronic components and offers thereby new functions and some

improvements.

The USB Ultra IR v2.0 indicates now with a red LED the receipt of infrared signals.

A green LED indicates that a power on/off signal is received which was programmed before.

Furthermore a new TSOP receiver unit is used, which is more sensitive and more energy efficient.

Last but not least the USB wiring was optimized, so that the operation also with all newer PCs and current motherboards should be no problem, since the USB data lines are now reduced to 3.3V instead of 5V.

All other functions are explained exactly on the following pages, thus much pleasure with reading and soldering.

The USB Ultra IR v2.0 indicates now with a red LED the receipt of infrared signals.

A green LED indicates that a power on/off signal is received which was programmed before.

Furthermore a new TSOP receiver unit is used, which is more sensitive and more energy efficient.

Last but not least the USB wiring was optimized, so that the operation also with all newer PCs and current motherboards should be no problem, since the USB data lines are now reduced to 3.3V instead of 5V.

All other functions are explained exactly on the following pages, thus much pleasure with reading and soldering.

Where is the sense of an infrared

receiver at the PC ...

If you like to

use the PC to watch television or S-VCD, DVD, DivX files or if you like to

build a

complete J-box II project with LCD display, etc. for the HiFi rack, you would also like to enjoy the comfort

to remote control all applications of this PC easily from the sofa.

complete J-box II project with LCD display, etc. for the HiFi rack, you would also like to enjoy the comfort

to remote control all applications of this PC easily from the sofa.

So the

first Luxus/Lowcost infrared receiver circuit was published

in July 2002 on ocinside.de and the goal was

a remote controlled PC with a connection to the serial port.

The next development was the USB infrared receiver guide to control the PC with a conventional remote control unit,

but with an USB connection instead of using the serial port.

So, there're a few ways to manage this very comfortable - may be with the well-known Luxus IR, Lowcost IR,

USB IR, or with the new USB Ultra infrared receiver which is now also offered as a complete kit in the Fanshop.

a remote controlled PC with a connection to the serial port.

The next development was the USB infrared receiver guide to control the PC with a conventional remote control unit,

but with an USB connection instead of using the serial port.

So, there're a few ways to manage this very comfortable - may be with the well-known Luxus IR, Lowcost IR,

USB IR, or with the new USB Ultra infrared receiver which is now also offered as a complete kit in the Fanshop.

That is new at the USB Ultra infrared

receiver 2.0 ...

Well, but what

can the USB Ultra IR receiver contrary to conventional infrared receivers ?

Very simple - on the one hand it receives the signals to send it to the PC Software (like Girder, WinLIRC, etc),

but on the other hand it can also compare infrared signals to power off or power on the PC.

So it's possible to remotely power on the PC (ATX Power Button, WoL, etc.), watch a film or hear some music and

hardware side power off the PC.

The PC can thus be completely controlled with a usual remote control unit (38 kHz RC-5) e.g. of the television,

or another HiFi component and/or all universal remote control units.

And since the latest version 2.0 this is additionally shown with two light emitting diodes.

Very simple - on the one hand it receives the signals to send it to the PC Software (like Girder, WinLIRC, etc),

but on the other hand it can also compare infrared signals to power off or power on the PC.

So it's possible to remotely power on the PC (ATX Power Button, WoL, etc.), watch a film or hear some music and

hardware side power off the PC.

The PC can thus be completely controlled with a usual remote control unit (38 kHz RC-5) e.g. of the television,

or another HiFi component and/or all universal remote control units.

And since the latest version 2.0 this is additionally shown with two light emitting diodes.

Take some

pretzel sticks or chips, loll on the sofa and watch TV, hear music, etc. :-)

These units are necessary ...

1x Vishay TSOP 31238 (38 kHz

infrared receiver)

1x Atmel ATtiny45-20PU (this IC have to be programmed like in the Fanshop !)

1x Atmel ATtiny13V-10PU (this IC have to be programmed like in the Fanshop !)

2x 8-pin IC-Socket

1x optoelectronic coupler CNY17-2

1x 12MHz quartz

2x Zener diodes 3.6V

1x red low-current LED

1x green low-current LED

1x 4.7µF / 16 volt capacitor (Elko or Tantal) vertical construction

1x 100nF capacitor (ceramik, layer or multilayer) vertical construction

2x 22pF ceramik capacitors vertical construction

3x 1.5 K resistors (0,25 watt)

2x 68 Ohm resistors (0,25 watt)

1x 390 Ohm resistor (0,25 watt)

1x 2-pole strip for the jumper

1x Jumper

1x Printed circuit board (PCB); approx. 6.8 x 3.2 cm with 25 x 12 holes is sufficient

1x USB A-Plug

1x approx. 1 meter shielded data cable with at least 4 pins

(alternatively a finished USB cabel with A-plug like in the fanshop kit can be used)

1x 2-pole cable approx. 1,5 meter

1x Atmel ATtiny45-20PU (this IC have to be programmed like in the Fanshop !)

1x Atmel ATtiny13V-10PU (this IC have to be programmed like in the Fanshop !)

2x 8-pin IC-Socket

1x optoelectronic coupler CNY17-2

1x 12MHz quartz

2x Zener diodes 3.6V

1x red low-current LED

1x green low-current LED

1x 4.7µF / 16 volt capacitor (Elko or Tantal) vertical construction

1x 100nF capacitor (ceramik, layer or multilayer) vertical construction

2x 22pF ceramik capacitors vertical construction

3x 1.5 K resistors (0,25 watt)

2x 68 Ohm resistors (0,25 watt)

1x 390 Ohm resistor (0,25 watt)

1x 2-pole strip for the jumper

1x Jumper

1x Printed circuit board (PCB); approx. 6.8 x 3.2 cm with 25 x 12 holes is sufficient

1x USB A-Plug

1x approx. 1 meter shielded data cable with at least 4 pins

(alternatively a finished USB cabel with A-plug like in the fanshop kit can be used)

1x 2-pole cable approx. 1,5 meter

The function and the circuit diagram of the USB Ultra IR receiver

v2.0

The USB Ultra IR receiver v2.0 functions ...

First I would like to explain here briefly, what the USB Ultra IR

v2.0 receiver makes at all.

When the TSOP31238 receives a RC5 coded infrared signal, it gets

on the one hand directly to pin 7 of the

programmable ATtiny45-20PU Atmel IC.

This Atmel IC, is clocked in the circuit with a 12 MHz quartz and

provides a communication between the Infrared receiver and the PC, so that this

signal can being processed by infrared receiver programs like Girder.

The 1.5 K resistor is as Pullup resistor between the negative data

line and the 5 V power supply

of the USB connetor to stabilize the logical signal.

The two 3V6 Zener diodes with the 68 ohm resistors limit the

voltage at both USB data lines Data+ and DATA-,

so that they finally only get approx. 3.3 V instead of 5 V from the Atmel IC.

Further a red low-current (power saving) control LED is soldered

with a 1.5K resistor between DATA (Pin3) and +5 V VCC (Pin2) of the TSOP

infrared sensor.

The signal goes however not only to the PC, but also to the second

ATtiny13V-10PU Atmel IC,

which have to be programmed with a special firmware before and has the

following function:

- If the Jumper J3 is put in, the AVR IC save the valid RC5 code

of an infrared remote control in the integrated

EEPROM to compare it.

The desired key on the remote control for switching on and switching off the PC

is thus programmed.

As soon as a valid RC5 signal of the remote control arrives, a green low

current LED with a 1.5K resistance and the opto coupler with a 390 ohm resistor

is supplied with power.

- When the Jumper is then taken off, the small 8-bits AVR RISC

processor compares all incoming signals

with the stored signal of the EEPROM and if the two signals are equal, the opto

coupler is supplied with power.

Unfortunately the ATTINY13V-10PU Atmel IC cannot be programmed any

longer as simply as the AT90S2323 IC

in the USB

infrared receiver guidance, since Atmel changed some special Fuse bits which

prevents a programming

of the firmware with conventional ISP prommer (ISP = in system prommer).

For this reason I program the firmware with a more complex Atmel programmer

directly on the ICs and

offer them programmed as kit in the Fanshop.

Here I set also all fuse bits that this Atmel IC needs no external quartz or

resonator.

The opto-coupler and the solution to switch the PC on and off ...

After careful consideration and numerous tests I decided to pass

the switching signal of the Atmel IC

over a 390 ohms resistor to an opto coupler, which has the task, to connect its

2-pole output (pin 4 & pin 5),

as soon as the input pins (pin 1 & pin 2) got the switching voltage.

This output could be connected e.g. with a WoL (Wake on Lan) connector, where

we can also get the 5 Volt power.

However, then one would not have the ingenious advantage to additionally switch

its PC off.

For this reason I decided for better solution, where the output of

the opto coupler is connected directly

with the PC power Button parallel to the power Button connection of the

motherboard.

The circuit get its necessary 5 V power supply over an USB cable, because

current ATX Mainboards supplies the

USB port also with power when the PC is switched off if this is activated by a

Jumper (+5VSB) or in the BIOS.

If this is not the case, or the PC has no necessary PowerOn feature, it's

possible to get the 5 Volt power

over a small external 5 Volt regulated power supply unit.

To separate the 5 V USB power supply you could cut, for example, the VCC

connection from Pin8 of the ATTINY45 to Pin8 of the ATTINY13V or connect the

complete circuit simply to an active USB Hub with external power supply to

supply the circuit continuously with power.

Alternatively it would be possible to get it from the ATX power supply

connector directly. However a wrong wiring

would forgive no errors, therefore I would not like to continue here with a

detailed explanation.

A PC ATX PSU pinout can be found in our Forum - e.g. in this PC

power supply pinout topic.

It's easy to check if the USB port gets power when the PC is

switched off, with an optical Mouse at the USB port.

Because the lighting of the optical scanning continues in this case if the PC

is switched off.

Of course it's also possible to measure the voltage of the USB port.

And who would like to vary a little bit, can use the WoL connection of the

Mainboard.

Here is the circuit for the USB Ultra IR v2.0 guide ...

Here is the connection diagram of the old

USB Ultra IR v1.1.

Additionally I have also build another variant for the operation

of the power AND the reset button.

Here is a link to the special

POWER and RESET circuit.

If you would like to build this, you can order e.g. the USB Ultra IR v2.0 kit

in combination with the normal

Ultra IR kit and develop hereby the special reset & power circuit.

The soldering guide for the USB Ultra IR receiver

Enough theory, lets go to the practice ...

Here is a picture of the PCB layout with all construction units

for easy soldering.

Just watch it comfortably while your soldering iron (15-25 watt) is heating-up.

Here is the old

USB Ultra IR v1.1 solder guide.

The correct position of the construction units ...

First we begin to plug in the construction units as explained on

the 25 x 12 holes of the printed circuit board (PCB).

Bent the pins under the PCB a little bit, but please DO NOT shorten the pins, yet !!!

It is important that the small notches of the two IC sockets and the notch of the opto coupler with 6 pins

are showing upward.

The new Tiny45 IC got one small point instead of the notch to show the right direction.

It is also necessary to pay attention to the polarity of both zener diodes (Z-diodes) and both Light Emitting Diodes,

whereby the black ring of the Z-diodes have to show up to the direction of the IC notches.

The polarity of LEDs is shown on a picture later on.

Furthermore you must absolutely pai attention to the correct polarity of the small yellow 4.7 µF tantal capacitor,

where the positive pin must show likewise upward like the IC notches!

(beneath the 16 is a small plus (+) symbol to indicate the polarity of the construction unit).

With the other construction units there is no polarity, so that only the correct position is important there.

Bent the pins under the PCB a little bit, but please DO NOT shorten the pins, yet !!!

It is important that the small notches of the two IC sockets and the notch of the opto coupler with 6 pins

are showing upward.

The new Tiny45 IC got one small point instead of the notch to show the right direction.

It is also necessary to pay attention to the polarity of both zener diodes (Z-diodes) and both Light Emitting Diodes,

whereby the black ring of the Z-diodes have to show up to the direction of the IC notches.

The polarity of LEDs is shown on a picture later on.

Furthermore you must absolutely pai attention to the correct polarity of the small yellow 4.7 µF tantal capacitor,

where the positive pin must show likewise upward like the IC notches!

(beneath the 16 is a small plus (+) symbol to indicate the polarity of the construction unit).

With the other construction units there is no polarity, so that only the correct position is important there.

Here again a picture with the different tantal capacitor designs

and the polarity:

Here is a picture of the Z-Diodes / Zener Diodes polarity:

And here is a picture of the light emitting diodes polarity,

whereby the shorter pin with the larger connecting surface and the reflector

within the light emitting diode is the cathode/GND/ground/-/VSS.

The longer pin with the smaller connecting surface within the light emitting diode is the anode/+/VCC:

The longer pin with the smaller connecting surface within the light emitting diode is the anode/+/VCC:

Once again a photo with the right positions whereby we place the

LEDs later:

When all construction units except the LEDs are fixed attached, it

continues with the lower surface.

The 22pF capacitors of the quartz are not absolutely necessary but they are the

load capacity for the quartz and should be soldered to a quartz.

I've published another mirror-inverted picture so that one does not have to

turn always the PCB for the

detection of the right construction unit.

Here's the mirror-inverted

view ! for better

orientation on the lower surface ...

rot = red, weiss = white, grün = green, schwarz = black, Zum

Mainboard = to the mainboard power switch

spiegelverkehrt = mirrored

Correct bending and pinch off the pins ...

On the basis of the photo one should bend now simply all pins of

the construction units and pinch off the pins,

whereby one again should make sure 100% that all construction units are on the

correct position and

as above explained also paid attention to the correct polarity.

If you make an error in this step, it's later rather difficult to out-iron -

spend some time to bend all pins

as shown and cut all pins in the correct length! with a long-nosed pliers and a

small wire cutting pliers.

Thus the lower surface looks like after the bending all pins:

And in such a way looks the lower surface after cutting the pins:

Now solder only the shown parts ...

First we solder only all pins on the lower surface of the PCB as

represented on the following Picture.

Please do not solder everything, yet, but first times only each pin of the

parts, since we still need the cables.

Also absolutely consider here the free spaces, where no connection may be.

Now we solder still another small bridge (from one before cutted

pin) to the right side.

Simply bend one side approx. 2mm, put the wire, cut the correct length on the

other side and then solder,

so the bridge can not slip when soldering.

Now another solder bridge is added in the center of the two ICs.

Here we can also use simply a piece from the material cutted before.

Solder the red low current LED and the green low current LED ...

Now it is time for the two light emitting diodes, which must be

polarized absolutely correctly,

so that they can light up afterwards.

The red LED is placed directly to the TSOP, whereby the shorter pin (-) points

to the TSOP IR receiver.

The green LED is put in near the Atmel ATTINY13V IC, whereby the longer pin (+)

is soldered to the resistor

and the shorter pin (-) to the small GND solder bridge, which we soldered on a

while ago.

I consciously soldered the two LEDs now, because who ordered the

new small IR receiver box from the Fanshop,

of course would like to see the LEDs nevertheless. And this is only possible if

the LED pins are left very long,

so that the LEDs can be seen afterwards on the top side of the box.

One should put the LED pins so far into the PCB, until the longer pin is seen

approximately 8mm at the PCB bottom.

Who does not use the IR box, can solder both LEDs directly on the PCB.

And who would like to place the PCB inside of a PC or HTPC, can use a

2-pol cable in order to attach the LEDs for example in a drive front bezel or

in a Casesticker.

On the next picture you can see the four new soldered connections

- two of the red LED in the left above the TSOP and two of the green LED right

down near the lower IC socket.

Prepare the cables ...

If you like to relax a little bit, it's time to prepare the

cables.

All cables are stripped approx. 3-4 cm, the outside shield is

separated cleanly and then all individual wires

have to be stripped and tin-plated.

It makes sense to tin all wires to get the tin later easier and faster on the

wires.

Simply hold the soldering iron to the stripped wire and hold some tin to the

other side solder.

Repeat this with all wires.

Here is a small picture sequence how to strip it correctly ...

Put the cables into the right PCB hole ...

The small cable, which I could not unfortunately avoid in the

layout, one can get oneself simply,

cutting the USB cable or the 2-pole cable a few centimeter and taking one wire

of it.

Strip the wire approx. 2-3 mm, twine and tin-plate it as written before.

Now we put the cables with the explained colors in the correct

place into the PCB.

The four wires of the USB cable are soldered this way:

The red (VCC) cable is soldered to the middle TSOP pin, the 1.5 K resistor and the one side of the 100n capacitor.

The black cable (GND) is soldered to the Jumper and the other side of the 100n capacitor.

The white (or yellow) cable (DATA-) is soldered with the 68ohm resistor to pin 5 of the ATTiny45 IC and the

green (or blue) cable (DATA+) is soldered with the other 68ohm resistor to pin 6 of the ATTiny45 IC.

The red (VCC) cable is soldered to the middle TSOP pin, the 1.5 K resistor and the one side of the 100n capacitor.

The black cable (GND) is soldered to the Jumper and the other side of the 100n capacitor.

The white (or yellow) cable (DATA-) is soldered with the 68ohm resistor to pin 5 of the ATTiny45 IC and the

green (or blue) cable (DATA+) is soldered with the other 68ohm resistor to pin 6 of the ATTiny45 IC.

No comments :

Post a Comment

feel free and ask...